Introduction

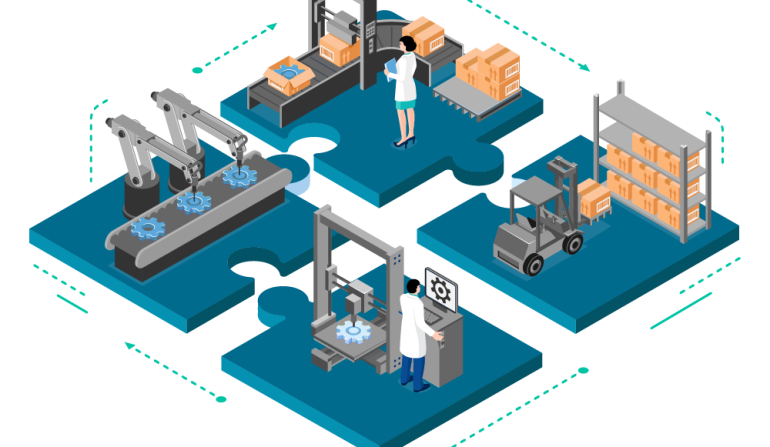

Manufacturing ERP software can be used and integrated into several business processes. A manufacturing company, small or large can benefit from ERP systems in various ways. Modern manufacturing companies need to use solutions and tools that help them step up their growth and establish data-driven culture to make informed conclusions at every step.

The power of analytics and big data can’t be disregarded considering today’s hyper-connected and data-driven environment. ERP systems not only help increase production and distribution but also offers a 360-degree view of the entire business by integrating distinct internal processes.

The accomplishment of the right manufacturing ERP software is quite hard. It requires you to consider different factors like your budget, accomplishment of goals, timeline and required features and functions. Enterprise Resource Planning system is a good investment for several industries.

What is Manufacturing ERP (Enterprise Resource Planning)?

Manufacturing ERP indicates Enterprise Resource Planning (ERP) software. It is used to plan, manage and deliver particular functionalities that support manufacturers and manufacturing business operations. Modern manufacturing ERP systems are constructed to flexibly support and integrate into any business process, creating an absolute business management platform for manufacturing companies.

Key Features of Manufacturing ERP

Manufacturing ERP systems offer a wide range of features and functionalities to enhance all business functions.

Here are the key capabilities of manufacturing ERP solutions:

- Issue Identification

- Inventory Management and Planning

- Compliance And Risk Management

- Quality Control

- Process Automation

- Effective Distribution Requirement of Planning And Management

- Distribution And Supply Chain Management

- Asset Management

- Finance And Accounting

- Bill of Materials

- Production Schedule Adjustments

- Greater Customer Details

Let’s understand the features which help an organization fast-track its growth.

1. Issue Identification:

One of the important reasons manufacturers accomplish ERP solutions? With a single data repository, it becomes simpler than ever to identify and resolve manufacturing issues. Hence look for a system that offers the ability to in-depth track the history of each product. You should be able to link together product description data, quality assurance records, and testing results to identify the precise touchpoint where the mistakes occurred.

In this way, you can take a proactive approach to issue resolution, other than a reactive one, where the stakes are higher and technical aspects of product development rather than spending important time assisting corrective efforts.

2. Inventory Management and planning:

Managing manufacturing companies’ inventory levels effectively to support production capacity is one of the greatest challenges for manufacturing companies. Inventory management comprises knowing your stock, product status, raw material management, finished products, purchase order tracking, and overall control. Modern manufacturing ERP systems include prime methods for inventory management, just-in-time, and material requirement planning (MRP) that help competently streamline inventories.

Look for an ERP solution that gives Material Requirements Planning (MRP) tools to help you calculate and plan your inventory levels so you can produce finished goods on time. Material Requirement Planning takes care of sales demand, product lead times, resource products at minimum inventory levels, and sales forecasts to predict product demand. Then the system generates the required purchase orders for raw materials and creates production orders.

3. Compliance and Risk Management:

The benefit of having an ERP system is that you don’t need to use another software to manage risk and compliance. ERP systems comprise this feature to keep track of all the various compliance and regulations related to your business. Today’s ERP systems are set up with such compliance and regulation things to help manage environmental, information security, and human resource regulations at every stage.

4. Quality Control:

Quality control means a set of standards that make sure a manufactured product meets quality goals defined by the organization. Quality is an important driver of success. As it will allow you to set and actively maintain desired levels of quality in every stage of the manufacturing process. Quality assurance is required in-depth examination and testing of the product.

ERP software helps to track and monitor several processes associated with quality management through alert mechanisms and monitoring at every level. Manufacturing defects in the end product can cost an organization not just regarding money, but also puts business reputation at stake.

5. Process Automation:

Technology makes it possible to automate everyday processes and thereby saves man-hours with almost no chance of man-made errors. It helps to save administrative hours that can be invested into higher-return activities. Manufacturing ERP offers total process automation that integrates several processes such as sales, purchases records, bill of materials (BOM), quality control, human resource, stock, human resources, etc. Automation not only saves time but allows organizations to access real-time data and have better control.

6. Effective Distribution Requirement of Planning and Management:

Manufacturing business requires proper requirement planning so that they can fulfill production needs. A complete ERP for manufacturing provides real-time data management and centralized data storage to forecast the demands and production requirements. Multi-level process management makes sure there is enough material and resources available to fulfill demands.

Today’s ERP system helps companies properly forecast demands and manage resources that eliminate waste and meet sales needs. Perfect manufacturing ERP software must also include modern analytics and business intelligence (BI) features to give total monitoring of various operations in the plant to make sure that all inventories are proper and appropriate for current manufacturing and delivery scheduling levels.

7. Distribution and Supply Chain Management:

For multi-store brands and retail chain businesses, distribution and supply chain management manages several components such as packaging, point of sale, warehousing, logistics vendors, and suppliers. Tracking requests for quotes from suppliers can help you stay on the path.

Your ERP solutions also provide reminders to follow up with suppliers and track incoming orders for raw materials so you can proactively balance your production schedule in case of delays. Effective distribution and supply chain management processes are very essential for a company’s longevity and growth.

8. Asset Management:

A good manufacturing ERP software gives users an asset management module that manages the factory’s physical assets and equipment. This helps companies decrease risk and cost and increase uptime and productivity.

9. Finance and Accounting:

ERP systems for manufacturing offer total management of the entire business. With several reports and business intelligence integrated tools, the finance and accounting module keeps track of all financial activity and documentation. This allows top management to properly monitor the process and plan future strategies.

It can be customized as per organizations’ needs where you can add/remove features as per the needs.

10. Bill of Materials:

The production bill of materials (BOM) is the structure of your finished good, outlining the components and quantities you required for production, including raw materials, resources (labor, machinery, etc.), and routing stages (the production steps like welding assembly, and many more). With a direct link to production scheduling, inventory, sales, purchasing, and finance, the BOM gives other departments with clear visibility into production costs and profitability. The bill of material is a difficult path to having an effective production line.

11. Production Schedule Adjustments:

What would you do if the president of your company asked you to put a particular product on the line tomorrow? Would you be able to respond quickly and appropriately to the request, or would it need hours of re-working your current setup?

The most powerful manufacturing ERP software systems allow you to answer this question in a matter of seconds. So you can simply run an inquiry and check your stock status. If you have sufficient on hand, you fulfill the demand on the spot. If not then you can check the open purchase orders and deliver an informed response on when the material will arrive.

12. Greater Customer Details:

Are you customer reps supplied with the data required to handle the customer requests they receive? Whether it’s a correcting request or an inquiry for more information, these team members should have every answer they need at the tip of their fingers. This is where an ERP platform comes in. With this centralized data platform, your reps can see a customer’s total history in a matter of seconds. This incorporates purchases they have made, conversations they have initiated, complaints they have issued, etc.

Conclusion

There are many difficult factors for manufacturing companies to consider when shopping for a new ERP system. After understanding the importance of these features, you come to know that manufacturing ERP software is a must.

Delight ERP software in Rajkot, Gujarat, India provides the best ERP software. As a leading ERP software provider, they have particularly designed to support the unique needs of the manufacturing industry.